-

HDDProcess

HDDProcess

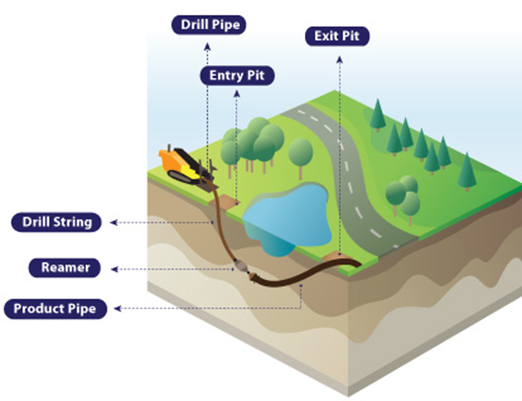

Directional drills are relatively compact with a small footprint, allowing them to get into tight spaces and situate on the side of the road without impeding traffic. A small crew is required: a drill operator, mud mixer/vacuum operator and a locator. The locator electronically tracks the progress of the drill head beneath the surface using a hand held locator. They then gather data from the Sonde located in the drill head just behind the drill bit. The Sonde gathers data such as location, depth, roll angle, pitch, and temperature to help the driller adjust the direction of the bit and control the bore path.

To prepare for the installation, the drill operator must first calculate the route, or bore path, of the pipe along a shallow, underground arc. The operator must also estimate the load applied to the pipe during pullback and select an appropriate pipe for the project. As he bores the path, a bentonite, polymer mix is injected into the hole to stabilize the hole, remove cuttings, reduce torque, lubricate the pipe, and cool the bit.

When the pilot hole has been bored and the bit emerges in the exit pit, the drill bit is removed. A reamer is placed on the end of the pipe string and pulled back to enlarge the bore hole. Generally the reamed hole is about 50% larger than the pipe.